|

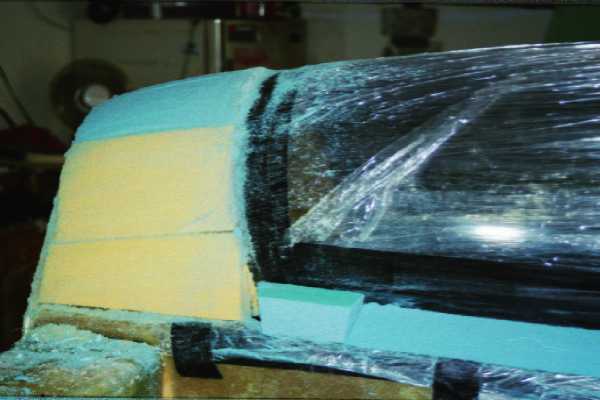

Foam is then added and the sanding begins. The foam was about three inches thick in places, and I was covered in

blue when finished.

After the foam is sanded, the glass layups are applied. A wood frame is built around the canopy to hold it when

removed from the fuselage. A dremel is then used to cut the foam in front of the canopy and on the turtledeck. The foam

will adhere slightly to the longerons, but saran wrap was laid over the longerons prior to the layup so it would not stick.

|

|

This is a closeup of the rear turtledeck portion after sanding.

The canopy is then removed and laid upside down on the bench. You cannot see here, but the foam has been removed

in the spots for the hinge and latch hardpoints. The inside foam is also sanded. The sides are left alone because

they match up with the longerons. The forward and turtledeck sections are sanded to about 1/3 inch thickness.

|