|

The next step is to cut out the baffles and ribs and one ply of bid is laid up on both sides. This is also different

than the plans. The fuel tank interior layups will be easier with one layer already on the ribs.

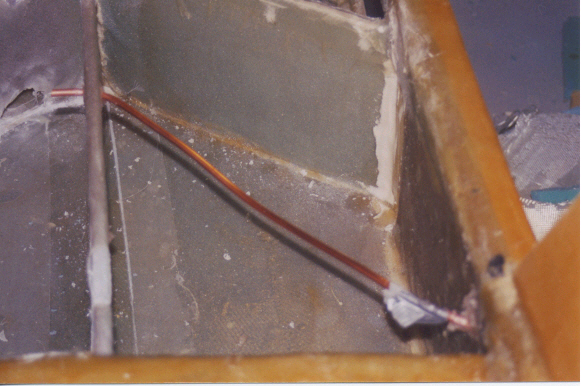

Above is a closeup of the baggage area. Not quite large enough for all the camping gear needed at Oshkosh,

but close. Below is a closeup of the fuel vent. The silver tape near the bottom right is covering the holes drilled

to allow the tank to vent when parked in the nose down position.

A thick bead of flox is then put down on the ribs. Then one last look at the inside of the tank, and the skin is

lifted up and placed carefully down on the ribs, taking care to sit directly down in one motion. Any side to side movement

could move the flox off the ribs and affect the seal. It is then weighted down for cure.

After both top layups are completed, the fuselage was placed in the space shuttle position to lay up the bottom of the

strakes.

|